|

|

Numerical Control Programming (G-Code) |

|

Part

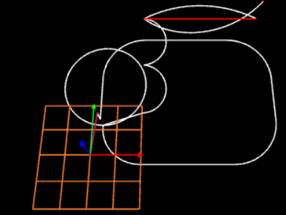

One: Program your initials using

G-code Given a 2.0” wide by 3.0” long piece of 0.375” aluminum, write a NC program that contains your initials. Design your initials on graph paper, being very careful to record all ordered pairs for the ends of each line segment, whether a straight line or arc. · The part must be squared up on both ends, and brought to 3.000 ±0.005. Do not leave a stock end with the machining marks from the horizontal saw. · When engraving, the center of the cutter must not come any closer to the edge of the stock than 0.25”. · Do not re-orient the block. The x-axis is 3.0, the y is 2.0. · Open your https://nraynaud.github.io/webgcode/ Software, and write your program. Be sure to verify the part. · Do not cut any deeper into the part than 0.015" (Z = -0.015). We use ½” center-drills for cutters here, and they work best at shallow depths for engraving. · All Z-axis moves, up and down, are done with a G01, and on a separate line of code. · Do not rapid traverse (G00) over (or through!) the part with Z lower than 0.1". · Name your part file your username: e.g.: rourkep. · Write your code in Notepad. The file extension will be .txt. This must be removed and replaced with .gcd. It must simply be filename.gcd. BE SURE TO TURN ON “VIEW FILE EXTENSIONS” · All parts will be inspected and compared at the completion of the module. The most detailed, intricate initials and designs will receive the highest grade. Be sure to use all the tools available to you to ease the computations. · Each of your initials should contain an arc. The design should also contain at least one arc. Part

Two: Your Design · Be sure to adhere to the rules above: remember, no closer to the edge than 0.25”. · Your initials and design both must contain at least one arc (G02 or G03). The more arcs, especially difficult ones (partial arcs) the better the grade. If either your initials or design do not contain an arc then you will receive a grade at or lower than a 50. Important Notes · Make sure you change the file extension from .txt to .gcd while the file is closed, and on the desktop. Otherwise you may get an empty file when sending it to the machine. Be sure to open your part file using notepad to make sure all the code is proper. · The first line of code N0010 must have an x-axis location, a y-axis location and a Z0.1 position. · The first line of code (N0010) is the ONLY line that the Z axis is on a line with x and y axis values. · All subsequent Z axis moves must be on a separate line of code. There are only two allowable values: Z0.1 and Z-0.015. BE CAREFUL. Be sure to use G01 on all lines containing Z moves.

Helpful links for g-code and partial arcs: ·

http://www.cnc-training.com/tandp/aug04.htm ·

http://www.instructables.com/id/How-to-program-arcs-and-linear-movement-in-G-Code-/ ·

https://www.cnccookbook.com/g-code-m-code-reference-list-cnc-mills/ |

|

Grading

Criteria: ·

Part

stock cut to proper length: 3.000 +/- 0.005” (10 points) ·

Extra

points for G-code written by hand. You

must submit a printed copy of the G-code for your initials for grading. (+10 points) ·

Extra

points for face milling. (+10 points) ·

Code

closer than ¼” to the edge of the part (25 points) |